Introduction to Types of Hydraulic Hoses

Types of Hydraulic Hoses: Complete Guide for Industrial and Mobile Applications. Hydraulic hoses are essential components in systems that transmit fluids under pressure to power machinery and equipment. These flexible tubes, typically reinforced with layers of wire or textile, connect pumps, valves, and actuators in various setups. In industrial and mobile applications, selecting the right type ensures efficiency, safety, and longevity. This guide explores the main types, their characteristics, and best uses, drawing on industry standards to help users make informed choices.

Thermoplastic Hydraulic Hoses for Precision Applications

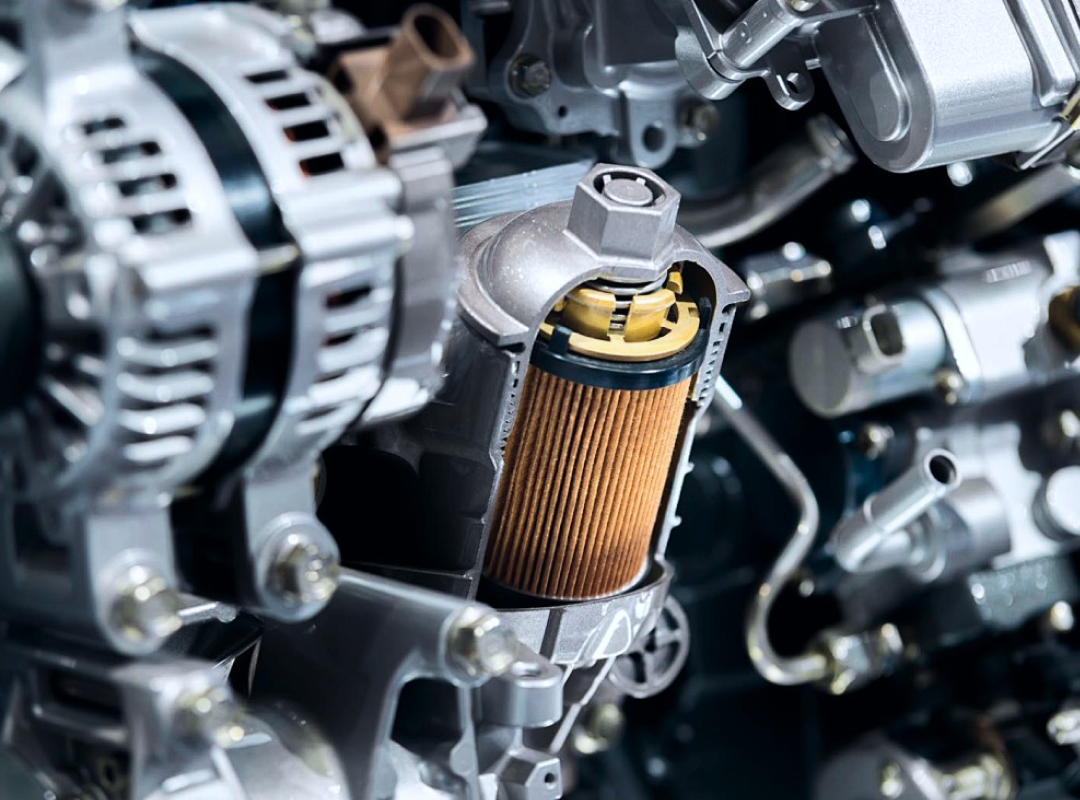

One prominent category among types of hydraulic hoses is thermoplastic hoses, valued for their lightweight construction and resistance to abrasion. Made from durable polymers like polyurethane, these hoses handle pressures up to 10,000 PSI and are ideal for mobile applications such as agricultural tractors and construction vehicles. In industrial settings, they suit clean environments like food processing where low permeability prevents contamination. A key advantage is their flexibility at low temperatures, down to -40°F, making them reliable in varying climates. Statistics from the National Fluid Power Association indicate that thermoplastic hoses reduce system weight by up to 50% compared to rubber alternatives, enhancing fuel efficiency in mobile machinery.

Rubber Hydraulic Hoses for Heavy-Duty Industrial Use

Rubber hydraulic hoses represent a robust option in types of hydraulic hoses, featuring synthetic rubber inner tubes reinforced with braided or spiral steel wires. These are engineered for high-pressure industrial applications, enduring bursts up to 6,000 PSI in mining and manufacturing equipment. Their oil-resistant covers protect against environmental hazards like chemicals and ozone, extending service life in demanding conditions. For mobile applications, such as excavators, rubber hoses provide superior flexibility and bend radius, minimizing kinking. Industry insights reveal that properly maintained rubber hoses can last over 10 years, reducing downtime costs by 30%, according to hydraulic engineering reports.

Hybrid and Specialized Hydraulic Hoses for Versatile Needs

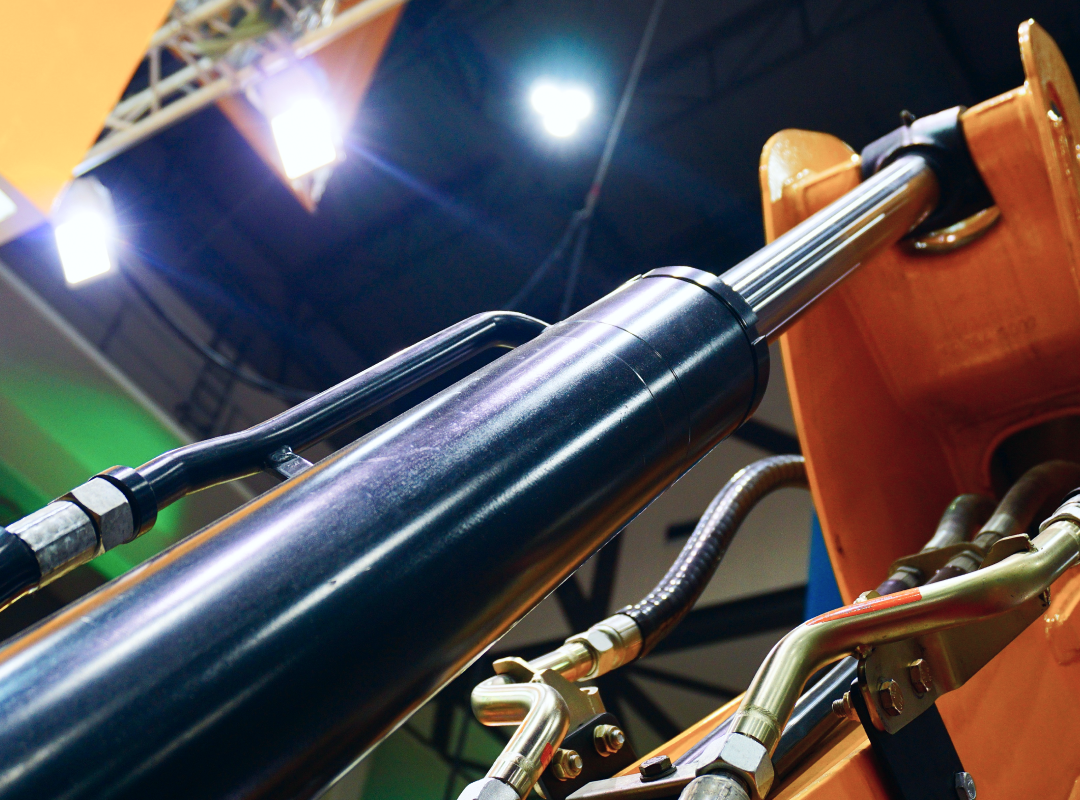

Hybrid types of hydraulic hoses combine materials like rubber and thermoplastic for optimized performance, offering a balance of strength and lightness in mixed industrial and mobile applications. For instance, compact spiral hoses excel in high-vibration scenarios, such as off-road vehicles, with pressure ratings exceeding 5,000 PSI. Specialized variants, including those with PTFE linings, resist extreme temperatures from -65°F to 400°F and are used in aerospace-derived mobile hydraulics. These hoses also incorporate anti-static features to prevent sparks in explosive environments. Data from ISO 1436 standards highlights how hybrid designs improve flow rates by 20%, boosting overall system productivity.

Selection Considerations for Industrial and Mobile Applications

When choosing types of hydraulic hoses, factors like operating pressure, temperature range, and fluid compatibility are crucial. Industrial applications often prioritize durability against constant loads, while mobile ones emphasize portability and weather resistance. Regular inspection for wear, adhering to SAE J517 specifications, can prevent failures that cost industries millions annually. For procurement, reliable suppliers offer customized solutions to match specific needs, ensuring seamless integration. This comprehensive understanding of types of hydraulic hoses empowers engineers and operators to enhance performance across sectors.

In summary, the diversity in types of hydraulic hoses caters to a wide array of industrial and mobile demands, from precision tasks to heavy lifting. By aligning hose selection with application requirements, systems operate more efficiently and safely.